|

This is a very multifaceted hobby and there are a dazling array

of supplies (e.g. tools and adhesives) that can be useful for

assembly, conversion, terrain making, etc. I will try to sort

them by categories. One online vendor of hobby supplies is: MicroMark.

If you know of more, contact me via my questions/comments

form. Also check out my Hobby

Materials Page.

Table of Contents

Chopper, The

|

The Chopper is a very handy little cutting device.

It mounts a single razor blade on a metal arm. The

cutting motion ends up being somewhat Guillotine-like,

allowing for clean cuts.

It is great for thin styrene material, especially

if it is solid. Magnetic strips also cut reasonably

well, provided they are placed in the chopper with

the paper backing facing up.

There are two guides with the Chopper that facilitate

reproducible cuts at 30, 45, 60, and 90 degrees.

|

|

|

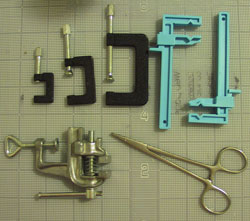

Clamps

Here are a variety of clamps that I find useful. The workhorse

in my model work are the blue plastic X-acto bar clamps.

|

Top left - X-acto c-clamps (metal)

Top right - X-acto bar clamps (plastic)

Bottom left - metal vise

Bottom right - hemostats |

|

Cutters/Clippers/Shears/Snippers

Here are a variety of clamps that I find useful. The workhorse

in my model work are the blue plastic X-acto bar clamps.

Cuticle clippers

- you can find these around the house

- sturdy and able to get into tight spaces

|

|

Xcelite 64CG

102 mm Cutters

Angled tip

(underside is hollowed) |

|

Xuron Microshears

Better at flush cuts

- this is the best sprue cutter I have used

- to protect it, I do not use it for anything else |

|

|

Cyanoacrylate Glue, a.k.a. Superglue,

Krazy Glue, etc. ($1; everywhere)

BE CAREFUL! This is fast bonding adhesive. It does not

fill gaps very well, but it bonds strongly and it bonds

different materials well reasonably well. If you have large

gaps between the pieces, you might consider epoxy resin

putty.

Warning: Fingers bond fastest. Your fingers will

stick together long before your parts do, if you feel tackiness,

pull away fast or you will be in an awkward position.

|

Drills & Rotary Tools

Of all of the following tools, the portable Makita handheld

power drill is the most indispensable.

If I lost my pin vise and Dremel tomorrow, I could continue

to use my Makita for all of the applications I have used

drills for with miniatures

| Dremel

Tool - A reuptedly handy little hobby gadget,

this is a high RPM rotary tool. It can be used

as a drill, cutter, polishier, cleaner, sander,

and a whole host of other functions. I have actually

found it to be far less useful than I had hoped.

Accessories I have found useful for miniatures

applications are the Dremel

Tool Drill Press (which also doubles as a convenient

stand), Dremel Tool

Flexshaft Attachement (this long snaky black attachment

allows more precise drilling), more collets (I

simply bought all four to be safe). Bit breakage

is a significant problem with this tool. If I were

to do it again, I would buy the variable speed

version that can operate below 1,000 RPM or simply

not buy it at all and use my Makita power drill. |

|

|

Pin

Vise ($5-$7) - Although I literally do use

it as a pin vise now, the name is a little misleading

and/or confusing to newcomers to the hobby. This

is a small metal handle that is almost exclusively

used as a manual drill in the miniatures hobby.

Simply slip a fine drill bit into it and tighten

down on the collet, just like a drill. It can

also be used to hold pins, if you like, which

is handy for marking a spot for drilling. This

tool takes the most time to use, trading speed

for control and feedback. Currently, I generally

only use my pin vise to hold the tip of a stick

pin for marking pilot spots on miniatures for

drilling.

Note: the dismantled vise

pictured at right shows that the collets are contained

within the body of the vise and that there are

four collet sizes to choose from.

Tip: check to make sure that

the butt of the vise (the hexagonal knob) rotates

freely before buying it. You should be able to

brace that with the palm/butt of your hand while

rotating the vise with your fingers.

|

|

| Power

Drill ($50+) - It has a variable speed trigger,

so I can control the speed quite nicely by squeezing

more or less on the trigger. The mass of the drill and

its speed makes it a little more stable than a pin vise

for pinning and the

lower speeds make it a lot safer than a Dremel Multipro. |

|

|

Drill Bits

Even if you have the set for the Dremel tool, you will

want a good selection of pin drill bits. Specifically:

- 0.030" - 0.032" for the pinning

I describe with paper clips.

|

Helping Hands ($6; an electronics supply

store, or a well-stocked hobby store)

These are cool and useful only occasionally, but when they

are, you really want to have them. They consist of a reasonably

heavy base on which a rod is mounted via a pivot. At each

end of the rod are additional pivots with alligator clips.

The base is not that fantastic of an anchor/ballast, but

it's OK; it will work, but keep in mind that you can easily

jar it during use.

|

|

Invaluable and nigh magical tools for cutting foam. :)

Seriously, your capabilities for shaping foam are tremendously

different given hot wire tools of various types. There are

simple scroll cutters, scroll tables, engravers, knifes,

etc. Here's a picture of a scroll table, which is hands

down one of the coolest tools (also in the picture is a

set of stairs I created by trimming the corner edges of

the blocks pictured in the back of the image.

Foamlinx is a little different as they provide CNC machines for foam cutting - basically, they can cut a computer-generated design out of foam automagically. Maybe a little high-end for a hobbyist, but hey, who knows? I have no direct experience with Foamlinx equipment, so I can not render an opinion on their functionality.

|

Knife - see the type of knife, e.g. Xacto

knife.

|

|

|

Needle File

Small thin files that are essential to thorough cleanup

of flash on models and minis. These are not all the same

in size. Testors's Model Masters series needle files are

quite fine and small. I would recommend buying a "normal"

size set as well as the Model Masters set. They have their

different uses.

|

Plastic Cement/Glue

A generic term that usually refers to a cement used to

bond styrene surfaces. It is variously called Plastic Glue,

Polystyrene Cement, Plastic Cement, etc. I currently use

three bottles of plastic cement - Faller Expert Plastic

Cement, Citadel Miniatures Plastic Cement, and Tenax Cement.

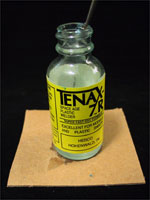

Tenax Cement ($3, 1 fluid ounce,

hobby store) - a.k.a., "Tenax-7R Space Age Plastic

Welder, Super Fast-Dry Formula." I primarily use Tenax

Cement for quick flash removal.

It is the thinnest and quickest drying of the plastic cements

I own. It claims to be a strong and fast-drying glue, but

I honestly have not taken advantage of it as a cement.

| A picture

of Tenax-7R Space Age Plastic Welder (I love saying

that every time). Notice the cardboard square I superglued

to the base. This is a safety measure to avoid tipping

the bottle over, which can happen suprisingly easily

and frequently when you get into some high speed flash

removal. Also be aware that Tenax evaporates quite quickly.

You should have a reasonably well ventilated workspace

and you should buy a replacement bottle when your current

one is about a quarter full. I personally move on to

the next bottle when it is about 5-10% full as there

is a slurry of flash and cement by that time. |

|

Faller Expert Plastic Cement ($4.50,

1 fluid ounce, hobby store) - Faller Expert Plastic

Cement is my favorite for plastic bonding. Currently, I

only use my Faller Expert Plastic Cement for precision application

of glue missed when I did the bulk of the glue application

with Citadel cement. I am very happy with Faller and the

precision applicator is not only great because of its precision

but also because it does not clog.

Citadel - I bought the Citadel Minatures Polystyrene

Cement when I first received my first Warhammer 40k army

because I did not know the cement types very well and I

felt most comfortable buying what was made by the company

that made my plastic miniatures; I will probably just us

it until it is empty and then use just Faller. Clogging

is a problem with this cement. I have to keep a sewing pin

in the tip to keep it clear for use. The opening is large

enough that it is awkard to apply cement sometimes and more

than once I ended up with a lot more cement than I wanted.

Residue accumulates easily and heavily on the tip, which

makes for some stray application that is unwanted.

|

Saws

Hack Saw

I keep a tiny little hack saw around for cutting materials

too sturdy for my Hobby saw. It's not vital, but it is handy

and not that expensive.

Hobby saw w/ mitre box

This is a very handy tool. It's not just good for cutting

bass wood and balsa wood. It is also great for cutting styrene,

especially large diameter tubes that would deform from typical

styrene cutting methods.

Jeweler Saw

This is great for conversions. It allos fine precise cuts.

The blade is delicate though, so be careful.

|

Seam Scraper ($10)

This is a cool little gadget made by Squadron Supplies.

It is a double-ended tool made of metal that simply has

curved scraper ends. This allows flash to be scraped off

with smooth strokes and the angle of the scraper does not

allow it to catch and gouge, because the edge pulled along

the surface. The effect is a tool that very quickly, cleanly,

and safely cleans flash off of smooth long surfaces. It

can also be used to whittle/sculpt down a surface somewhat.

|

Stylus ($2)

This is a tool for sculpting that has a round ball shape

at the end.

|

| This is my

double ball stylus. The smaller ball is 0.030"

in diameter, the larger one is 0.045" in diameterOne

ball is smaller than the other onea fine tip, the other

is a little larger. I find it very useful. |

|

|

|

Florist Wire ($?; craft store)

This is a reasonably stiff wire that is still somewhat

malleable. It can be used to help hold things in place

and/or add structural integrity to something. Florists

use it for constructing displays.

|

Xacto Knife ($2-$15, hobby or crafts

store, general purpose shops)

You have to get at least one of these. This is the standard

hobby knife. It is typically used with a triangular blade

(#2 blade?). There are two primary blade choices. A sturdy

thick triangular blade or a thinner, longer, finer triangular

blade (#11 blade). The former is great for most work, while

the later is nice for working in tight spaces or times when

you want the blade to flex a little. If you are planning

to put a lot of twisting force on the blade, you should

probably use the heavier blade and wear some protective

glasses so that if the tip snaps off, you won't damage your

eyes. I personally have a few knives. I always keep one

standard knife with a standard tip handy as well as a slimmer

gripped fine tip knife. Changing the blades out gets annoying

and the different grip sizes really are well suited to their

use.

|

| This is the

Xacto I use most. It has a nice soft grip, a sharp #11

blade, and the back end has a hexagonal washer/cuff

around it which prevents it from rolling around (safety

first!). |

|

| And here is

my uglier knife <grin> the one that keep around

to assist in removing pieces from assembled models and

heavy knife work. |

|

|